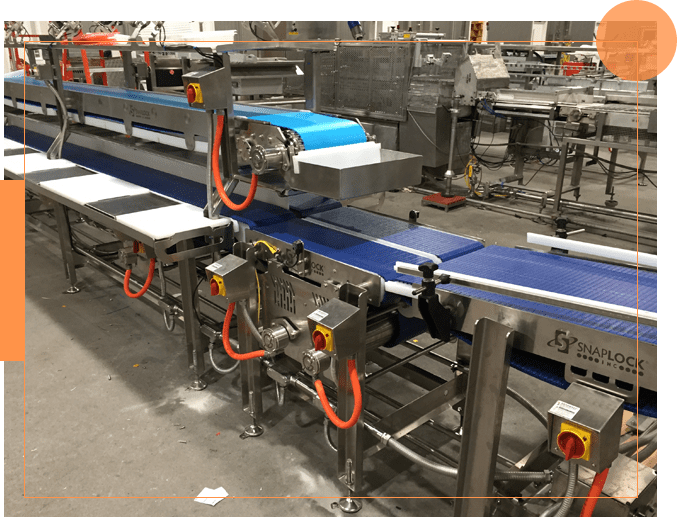

Stainless Steel Conveyor Systems

Snap Lock, Inc., specializes in innovating stainless steel sanitary conveyor systems tailored to the food industry with focus on RTE / ready-to-eat for meat and poultry as well as baking, frozen dough, sea food and other direct food contact applications. With a vast array of configurations, our modular conveyor solutions are designed to elevate the efficiency and cleanliness of your operations resulting in return on investment past the point of purchase.

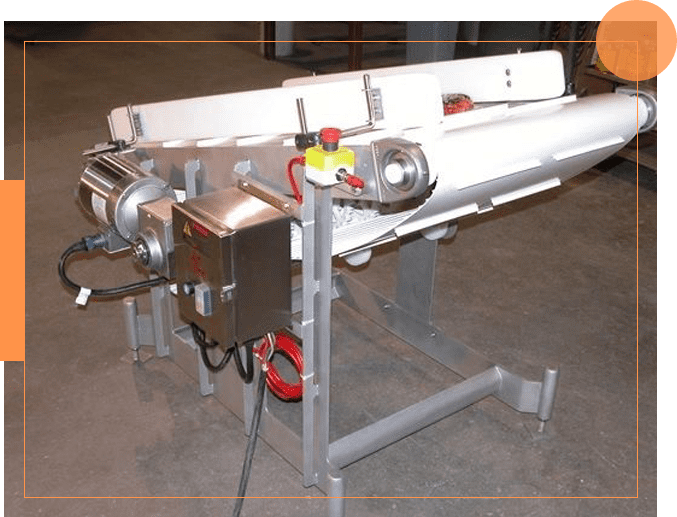

Welded Conveyor

Ideal for ready-to-eat applications, our Snap Lock, Inc. Welded Conveyor ensures premium quality.

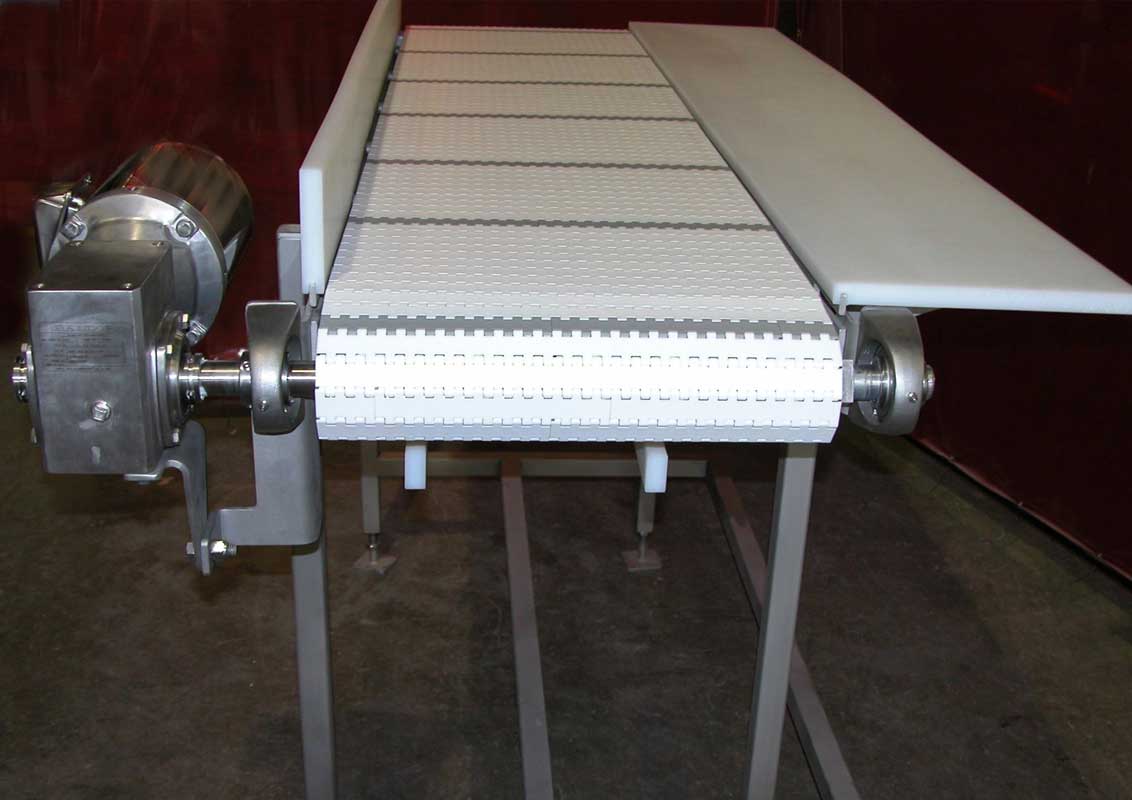

Bolted Conveyor

Maximize modularity with our Snap Lock, Inc. Bolted Conveyor. Reuse and reconfigure conveyor frames for updated process layout changes.

Materials

Materials to meet your needs, 304/303 stainless steel and UHMW food-grade plastic. Industrial and unique order options include carbon steel, galvanized and aluminum.

Nose Bars

Optimize product transfers points as well as reduce maintenance and sanitation. No moving parts reduce pinch points and eliminate bearing failure.

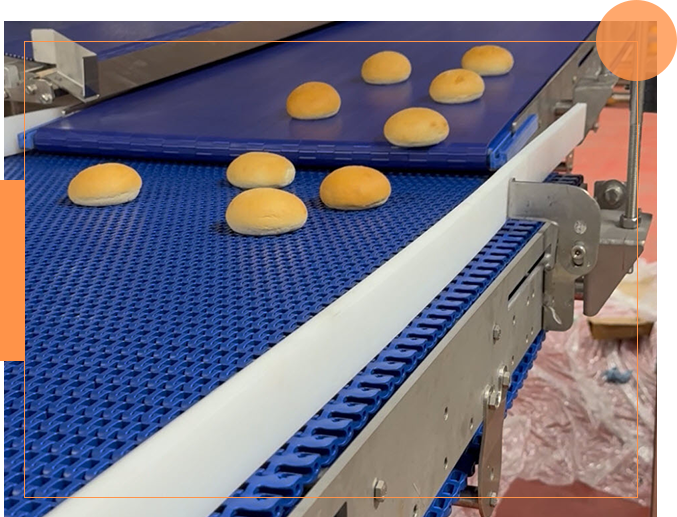

Conveyor Belting

Belting options, including plastic modular, thermo plastic, fabric, wire belting and others.

Gearboxes

Our stainless-steel gearbox and motorized pulleys are ideal for food and wash down applications. For light washdown and other industrial application we offer our E-coat and painted options.

Motors

Our stainless-steel Motors and motorized pulleys are ideal for food and wash down applications. For light washdown and other industrial application we offer our painted options.

Control Systems

Redefine automation with Snap Lock, Inc.'s pre-engineered modular controls or our customized control systems. Our experts can design systems to enhance efficiency and throughput, meeting your project requirements effectively.

Customizable Solutions for Your Specific Needs

SNAP LOCK’S ADVANTAGES

Snap Lock conveyors offer several advantages due to their customizable nature, which allows tailoring solutions to specific needs:

Explore Specifications

Explore our conveyor specifications for unparalleled efficiency and innovation. From belt materials to motor specifications, our cutting-edge technology revolutionizes operations. Whether you need versatility, durability, or precision, our specifications streamline processes for success. Elevate your business with industry-leading conveyor solutions—explore our specifications now!

Ready to elevate your operations with Snap Lock, Inc.'s premium conveyor solutions? Connect with us now to request a quote tailored to your needs. Our team is dedicated to providing you with the best possible solution for your application.

Food Grade Conveyors

Hygienic sanitary conveyor design to meet the most stringent standards

Industrial Conveyors

Our industrial conveyors utilize our same Snap Lock basic design with the primary difference being material type. Our Industrial conveyors and components can interchange and connect to our hygienic stainless steel conveyors.

We also offer other complementary industrial equipment:

Features

Light Duty Conveyor

Medium-Duty Conveyor

Heavy Duty Conveyor

Extra Heavy-Duty Conveyor

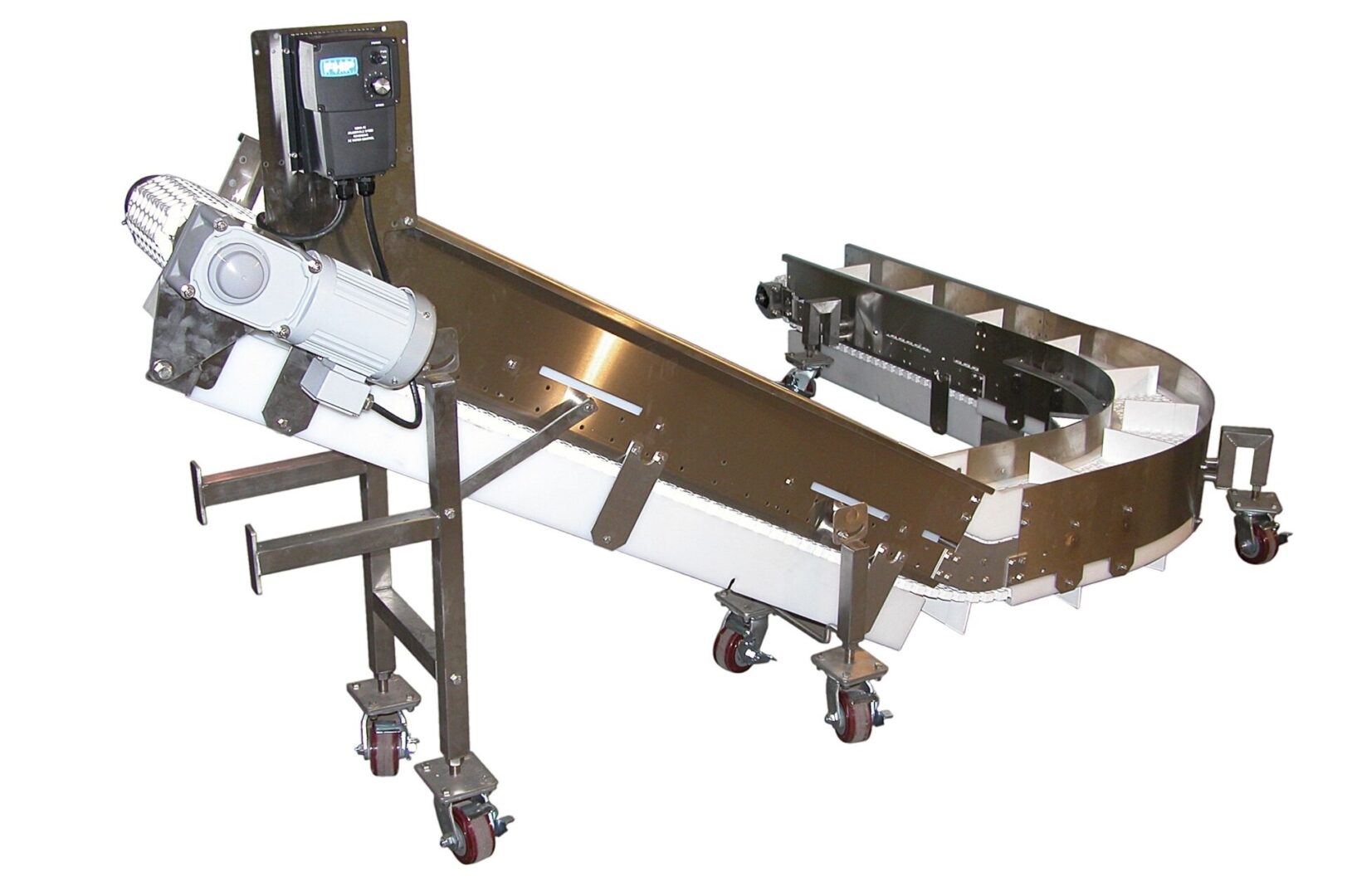

Radius Conveyor

Please note that Radius Conveyor is available in extra heavy, heavy, medium, or light duty.

Control Systems

Customize your control system with Snap Lock, Inc. to align perfectly with your plant's requirements. Our Plug & Play Emergency stops are designed for easy installation by your staff, even without an electrician.

Get a Customized Quote

Our duty series are all based on Snap Lock, Inc.'s unique patented conveyor design, and crafted with high-quality materials, ensuring compatibility across all options. At Snap Lock, Inc., customers can select from four different duty series when choosing their configuration. This ensures that each customer receives the ideal conveyor solution tailored to their application needs and budget. When requesting a quote, please consider the following factors: product application, environmental severity, series features, and cost. Request a quote today!